Supply chain and procurement teams are like the unsung heroes in any company. They are both crucial, but they tackle different parts of the process.

Think of the supply chain as a product’s journey to reach customers. It starts with raw materials and moves through design, sourcing, production, logistics, inventory, and distribution. Each stage is like a link in a chain, and they all have to work smoothly together to ensure everything runs well.

Supply chain management (SCM)) and procurement both play important roles here. SCM ensures that each part of the process—from start to finish—flows efficiently, while procurement focuses on finding and buying the materials needed. Together, they keep track of inventory, organize the logistics, and keep products moving.

The goal is to cut costs, improve quality, and strengthen the company in the market. For managers, it is all about balancing demand, controlling expenses, and maintaining quality at each stage.

In this article, we will briefly discuss what sets procurement apart from supply chain management, especially regarding supplies. You will see how both roles work together to keep goods flowing and the business thriving.

But let us begin with the basics and understand procurement and supply chain management.

What is Procurement?

Procurement is the process organizations use to procure the goods and services they need to operate. It includes steps like identifying what is needed, selecting vendors, agreeing on prices, and making sure deliveries arrive on time.

However, procurement is more than just buying things; it is about making sure the organization gets good value. Procurement also helps build strong partnerships with vendors and ensures that each purchase supports the organization’s goals.

For example, suppose a tech company needs new laptops for its development team. Here is how the procurement process works:

- The team identifies how many laptops they need and the required specifications.

- They research vendors offering high-quality laptops.

- The team negotiates prices, delivery dates, and warranty terms.

- Laptops are scheduled for delivery before the next big project.

- Upon arrival, the laptops are checked to meet quality and technical standards.

- The company builds a strong relationship with the vendor for future needs.

Such a streamlined procurement-to-pay process ensures the company gets the right laptops at a fair price and on time.

Step-by-Step Guide to the Procurement Process

The procurement of supplies involves several key steps to make sure organizations get the supplies they need at the right time and cost. Each part—from identifying needs to managing vendors—is essential for keeping things running smoothly and efficiently.

Step 1: Identifying Needs

Knowing exactly what the organization needs is important before buying anything. This can be for shortages, new projects, or everyday operations.

Step 2: Researching vendors

After figuring out the needs, the next step is to find good vendors. This means looking at options based on price, quality, reliability, and reputation.

Step 3: Negotiating Terms

Here, the organization agrees on terms with the vendor, including price, amount, delivery dates, and payment conditions.

Step 4: Issuing Purchase Orders

Once terms are agreed upon, a purchase order (PO) is sent to the vendor. This document explains exactly what is being bought.

Step 5: Receiving and Inspecting Deliveries

When the goods or services arrive, they are inspected to ensure they meet the agreed requirements and quality levels.

Step 6: Processing Invoices and Payments

After confirming quality and delivery, the procurement team checks and pays the vendor’s invoice promptly.

Step 7: Managing vendor Relationships

Procurement is not just about one-time buys. Building strong relationships with vendors can lead to better deals, discounts, and future teamwork.

Step 8: Overseeing Contracts

Contract management is vital for large or long-term purchases. This includes tracking performance, making sure terms are met, and renegotiating when needed.

Step 9: Handling Risks

It is essential to plan for potential problems, like supply chain delays, and have steps in place to handle them smoothly.

Step 10: Reviewing and Improving Processes

Regularly reviewing procurement methods can reveal areas for improvement, saving time and money. This might involve checking vendor performance and finding ways to cut costs.

What is Supply Chain Management (SCM)?

Supply chain management is the system that gets raw materials, transforms them into finished products, and finally delivers them right to the customers. SCM pulls vendors, manufacturers, and distributors into one streamlined network, ensuring that products flow smoothly and costs are controlled.

In a well-run supply chain, every piece—from raw materials to the final product—has a part to play, and it all depends on good planning, control, and constant monitoring. However, SCM is not just about moving products from point A to B but also about managing information, finance, and vendor relationships. This coordination makes sure customers get what they need on time and in top shape. In the big picture, SCM helps companies build strong partnerships with vendors, reduce spending, and reach their business goals.

Key Goals of Effective Supply Chain Management

Supply Chain Management keeps companies competitive by creating a smooth, efficient flow of goods. SCM focuses on making sure each part of the supply chain works together to meet customer needs and company goals. Here are the main goals of SCM:

1. Efficiency and Cost Control

SCM moves goods quickly while cutting waste and keeping costs low. By improving each step, products reach customers faster and at a better price without lowering quality.

2. Quality and Consistency

A good supply chain keeps high standards at every stage. This ensures products meet strict requirements, giving customers reliable, high-quality goods.

3. Flexibility and Adaptability

Supply needs and market demands can change fast. SCM builds a flexible supply chain that adapts easily to changes, avoiding delays or issues.

4. Risk Management and Reliability

SCM identifies risks and prepares for possible disruptions. This keeps the supply chain steady and reliable.

5. Sustainability and Responsibility

SCM focuses on meeting business goals while caring for social and environmental impacts. This means sourcing responsibly, reducing waste, and following ethical practices.

6. Customer Satisfaction

Aligning supply chain goals with customer needs ensures products arrive on time and in good shape. This builds customer trust and loyalty.

7. Innovation and Improvement

SCM adopts new technologies and ideas to improve the supply chain. It looks for ways to boost efficiency, quality, and flexibility.

8. Visibility and Control

Full visibility helps companies make informed decisions. This gives more control over each step, leading to efficient and well-managed operations.

Key Differences between Procurement and Supply Chain Management

Procurement and supply chain management work closely together but focus on different parts of the product journey. Procurement is a subset of SCM. To understand these roles, it is helpful to see what each one does, how they connect, and their unique goals.

1. Focus and Scope

Each has a different focus area that helps support the business.

- Procurement:

Procurement of supplies focuses on getting the materials and services a business needs to operate. This includes selecting vendors, negotiating contracts, and managing orders.

- Finds and chooses reliable vendors

- Manages contracts to ensure terms are beneficial for the company

- Oversees the purchase of raw materials, goods, and services needed for production

- Supply Chain Management:

On the other hand, SCM manages the full flow of goods and services. This process begins with sourcing raw materials and ends with delivering the final products to customers.

- Coordinates each step in the product’s journey, from raw materials to the customer

- Oversees storage, transportation, and delivery to keep things efficient

- Connects every stage for smooth, cost-effective operations

2. Strategic vs. Operational Role

Procurement and supply chain management each play unique roles within a business. Both bring important strategies, but they approach their goals in different ways.

- Procurement:

Procurement focuses on operational tasks. Its main job is to manage the day-to-day flow of materials to keep things running smoothly. This involves finding the right goods at the right price from the best vendors.

- Keeps costs low and ensures quality in purchasing choices

- Handles routine tasks like managing vendors, placing orders, and monitoring contracts

- Makes sure resources are available when needed to avoid delays

- Supply Chain Management:

SCM has a broader, strategic role. It includes purchasing and coordinating all supply chain activities to keep the process efficient and quick.

- Combines planning, sourcing, manufacturing, and delivery into one system

- Aims for long-term goals like better efficiency, reducing risks, and improving customer satisfaction

- Works closely with procurement, storage, transportation, and distribution to keep everything connected

3. Objectives

Each function has clear goals that shape its actions and choices, making procurement and supply chain management essential but different in purpose.

- Procurement:

The main goal of procurement is to get resources at the best value while keeping high quality. Procurement focuses on securing goods and services that fit the business’s needs and budget.

- Aims to save costs without sacrificing quality standards

- Builds strong connections with trustworthy vendors

- Ensures timely delivery of goods to avoid delays in production

- Supply Chain Management:

SCM’s goals extend beyond just purchasing. It aims to create a steady, cost-effective flow of goods through each stage, meeting customer needs and supporting business targets.

- Works to reduce total operating costs and improve efficiency

- Ensures quick, reliable delivery of products to customers

- Aims to boost customer satisfaction through on-time, accurate fulfillment

4. End-to-End vs. Sourcing Focus

Procurement and Supply Chain Management each play important roles in a product’s journey, from sourcing to delivery. Both contribute to making this journey as smooth and efficient as possible.

- Procurement:

Procurement is focused mainly on sourcing. It works to secure the goods or services that a company needs. This means finding reliable vendors, setting fair prices, and creating contract agreements.

- Focuses on choosing the best vendors for materials

- Negotiates prices and contract terms

- Works with vendors to manage orders and check for quality

- Supply Chain Management:

SCM oversees the entire lifecycle of a product, from sourcing materials to delivering finished products. It combines procurement work with other key areas, such as warehousing, transportation, and distribution.

- Manages each part of the supply chain, from materials to final product

- Connects procurement, manufacturing, and distribution for a seamless process

- Ensures every part works together to save costs and speed up delivery

Let us understand the difference between procurement and supply chain management easily through this table format.

| Aspect | Procurement | Supply Chain Management |

|---|---|---|

| Focus | Direct purchasing of goods and services | End-to-end flow of goods from vendor to end user |

| Scope | Sourcing, negotiating, and buying | Includes procurement plus logistics, storage, and distribution |

| Timeline | Short-term, transaction-based | Long-term, strategic process |

| Key Activities |

1. Vendor selection 2. Price negotiation 3. Purchase order management 4. Invoice processing |

1. Demand planning 2. Inventory management 3. Warehouse operations 4. Transportation management |

| Main Goal | Cost savings and quality assurance | Optimize the entire supply flow and reduce total costs |

| Relationships | Direct vendor interactions | Multiple stakeholder coordination |

The Seamless Connection Between Procurement and Supply Chain Management

Procurement and Supply Chain Management are two closely connected functions that help businesses operate smoothly. While each has its focus, both functions rely on one another to ensure products move efficiently from vendors to customers. Let us look at how they work together in a seamless flow.

1. Starting the Chain: The Role of Procurement

Procurement is the first step in the supply chain. It focuses on finding and obtaining the goods and services a company needs. This includes picking reliable vendors, setting up contracts, and managing orders. Procurement also ensures that the needed materials or products are ready for the next steps in the supply chain.

- Finding Reliable Vendors: Procurement teams search for trustworthy vendors that provide high-quality materials.

- Setting Terms: They work with vendors to agree on fair prices and delivery times.

- Managing Orders and Contracts: Procurement tracks orders and builds relationships with vendors to keep supplies steady.

2. Connecting Procurement to Supply Chain Operations

Once procurement secures the supplies, Supply Chain Management takes over. SCM manages the journey of products, linking each part of the process—from warehousing to transportation and delivery. This link between procurement and SCM helps each step run smoothly.

- Warehousing Supplies: SCM stores goods safely to ensure they are ready for the next stage.

- Coordinating Transportation: SCM organizes the movement of supplies or products from warehouses to the next stop.

- Ensuring On-Time Delivery: SCM overlooks delivery to ensure customers get products when needed.

Procurement and supply chain management both focus on keeping costs low, ensuring high quality, and making the supply chain reliable. To meet these goals, they need to work closely together. For example, procurement might find a vendor with lower prices, but SCM needs to confirm that these materials are good quality before delivery.

- Cost Control: Procurement negotiates good prices, while SCM organizes transport to decrease overall costs.

- Quality Assurance: Procurement ensures vendors meet standards, and SCM checks quality at each stage.

- Reliability: They keep the supply chain steady so products arrive on time and in the right place.

4. Helping the Supply Chain Stay Flexible and Responsive

The link between procurement and supply chain management also helps businesses handle changes, like sudden demand increases or supply chain problems. By working together, they help the company respond quickly to these challenges.

- Adjusting Supply Levels: Procurement can change order amounts based on SCM’s feedback about demand.

- Finding New Vendors: If supplies are problematic, procurement can find new vendors, while SCM adjusts delivery plans as needed.

- Continuous Communication: A strong connection allows for real-time communication so both teams can make quick decisions when needed.

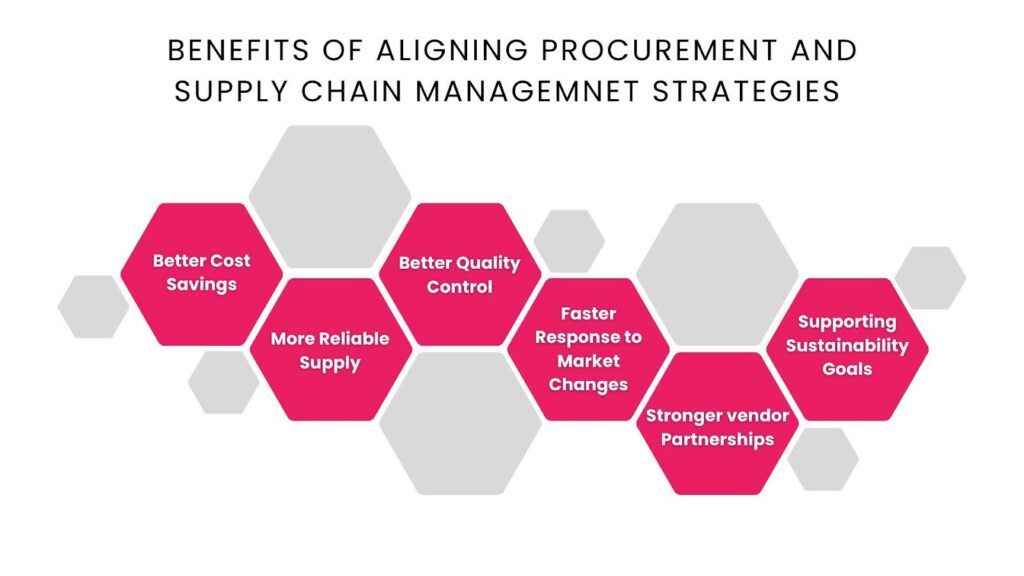

Benefits of Aligning Procurement and Supply Chain Management Strategies

When procurement and supply chain management work together, businesses can become more efficient, save money, and build better vendor relationships. Here is how aligning these strategies through procurement-to-pay software helps:

1. Better Cost Savings

Aligning procurement and supply chain management helps companies control supply costs and reduce unnecessary spending. Working together, they can plan smarter, negotiate better deals, and avoid delays.

- Bulk Discounts: By ordering together, companies can buy in larger amounts, which often leads to discounts.

- Lower Storage Costs: Good planning helps companies order just what they need, so they do not pay extra for storage.

- Reduced Shipping Costs: Aligned strategies allow companies to plan transportation better, which cuts down shipping expenses.

2. More Reliable Supply

When procurement and supply chain management are aligned, companies can get supplies on time without interruptions. This helps avoid shortages and delays.

- Better Demand Planning: By working together, teams can accurately predict how much supply is needed, avoiding too much or too little.

- Stronger vendor Relationships: Aligned efforts build trust with vendors, making it easier to rely on them for timely deliveries.

- Reduced Risks: A combined strategy lets teams spot potential problems early and quickly respond to supply issues.

3. Better Quality Control

When procurement and SCM work together, it is easier to maintain high quality throughout the supply process. Both teams ensure that quality standards are met from start to finish.

- Regular Quality Checks: Procurement sets quality rules, and SCM ensures these are followed at every step.

- Tracking vendor Performance: Working together helps teams monitor vendors’ performance, maintain high standards, and fix quality issues quickly.

- Quick Problem Solving: By working as a team, procurement, and supply chain management can solve quality problems faster to ensure supplies meet the company’s standards.

4. Faster Response to Market Changes

Aligning procurement and supply chain management helps a company react quickly to changes in demand or supply. This makes the business more competitive.

- Flexible Ordering: Working together, teams can adjust orders based on demand to avoid having too much or too little stock.

- Quick vendor Switches: If a vendor can not meet sudden demand, aligned teams can quickly switch to another vendor.

- Efficient Use of Resources: Procurement and SCM work together to avoid excess inventory and keep supplies in line with market needs.

5. Stronger Vendor Partnerships

When procurement and supply chain management are in sync, they build stronger relationships with vendors. These partnerships help with long-term growth and reliability.

- Clear Communication with vendors: Aligned teams provide clear and regular communication, which builds trust with vendors.

- Long-Term Contracts and Loyalty: Procurement and SCM make it easier to create long-term contracts, leading to better terms and loyalty.

- Better Collaboration: Strong partnerships allow vendors and the company to work together to improve efficiency.

6. Supporting Sustainability Goals

Aligned procurement and supply chain management strategies help companies reach their sustainability goals by making responsible choices and reducing waste.

- Eco-Friendly Sourcing: Procurement can choose vendors with environmental standards, while SCM supports low-waste logistics.

- Reducing Waste: Working together helps teams order the right supplies to cut down on surplus inventory.

- Lowering Carbon Emissions: Aligned strategies help teams pick smarter shipping and storage options, which reduces carbon emissions.

How Technology Powers Modern Procurement and Supply Chain Management?

Technology plays an important role in making procurement and supply chain processes better. New technology is changing procurement teams and improving the supply chain. Here is how:

- Automation and AI

Automation and artificial intelligence (AI) make procurement faster and more accurate. Finance automation tools handle repetitive tasks, reducing mistakes and saving time. AI can predict demand, help with purchasing, and control inventory. This allows teams to plan rather than react to last-minute needs.

- Blockchain for Better Transparency

Blockchain adds security and transparency to the supply chain. It creates records that can not be changed. This makes it easy to track products from the vendor to the customer, reducing fraud and confirming product quality.

- Internet of Things (IoT) for Real-Time Monitoring

IoT devices allow companies to monitor goods in real-time. Smart sensors can track shipments, check storage conditions, and manage inventory levels. With real-time data, companies can improve efficiency and cut down on delays.

- Advanced Analytics for Better Decisions

AI-based big data and predictive analytics help procurement teams see things clearly. With the help of AI, companies do not just notice simple patterns—they can find deeper insights, check how vendors are performing, and spot any risks early on. This means that teams can fix small issues before they become big problems, keeping everything running smoothly.

- Cloud Computing for Flexibility

Cloud platforms let procurement teams access data from anywhere. This makes it easier for teams in different places to work together. It also allows procurement to respond quickly to changes.

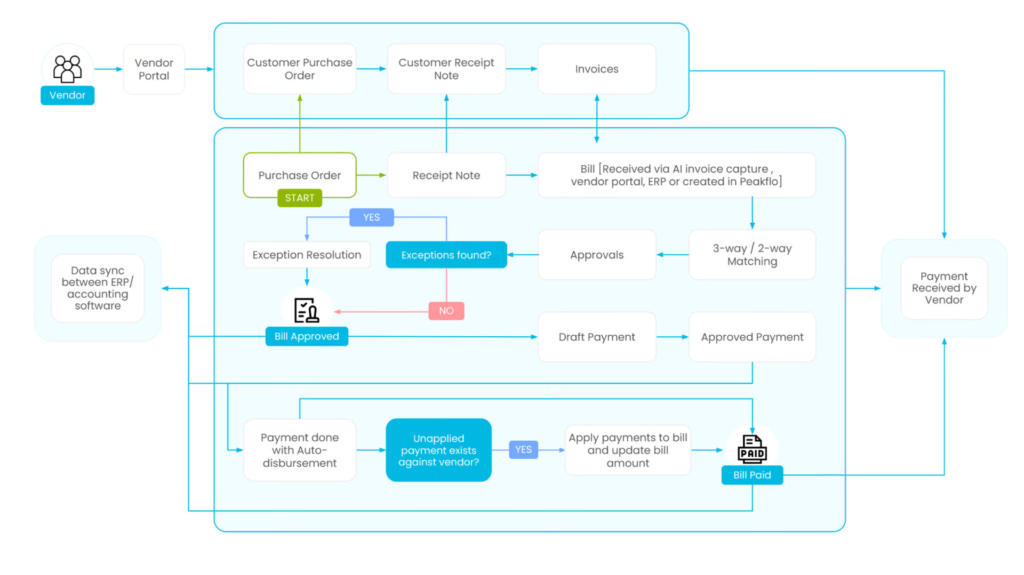

Peakflo: Powering Smarter Procurement and Supply Chain Management

Peakflo is like a super helper for your finance team! It makes managing spending and working with suppliers easier by keeping everything organized and automated. Here is how it helps:

- Accounts Payable Automation

Just think about this: you do not have to type in every bill or check each payment yourself. Peakflo takes care of bill entry, approvals, and payments automatically. This means fewer mistakes and faster payments to suppliers!

- Procurement Management

With Peakflo, ordering supplies is simple. You can make and manage purchase orders, set up approvals, and track all your orders in one place. It helps you stay on top of every order and vendor interaction, so nothing gets lost or delayed.

- Vendor Management

Peakflo gives you tools to easily onboard vendors, check their performance, and track which orders are still open or completed. This way, you can make better choices about who you work with and always have the information you need to make smart decisions.

- Integration with Other Systems

Peakflo easily integrates with other systems your team uses, like accounting and ERP software. This connection means all your data flows together without gaps, making your financial operations smoother and more accurate.

Take our product tour here to learn more.

Conclusion

All in all, procurement and supply chain management are teams that work together to keep everything moving smoothly. Procurement is like sourcing for the items you need—finding and buying materials. Supply chain management is the whole journey: getting those materials, making products, and delivering them to customers. Both are very important for ensuring everything is in the right place at the right time.

Peakflo makes things easier by handling the entire procure-to-pay cycle. It helps you quickly handle vendors, bills, approvals, and payments. So, instead of getting buried in paperwork, you can focus on keeping supplies coming and building strong relationships with suppliers.

Want to see how Peakflo can simplify your work? Book a demo to see how it keeps everything running smoothly and saves you time!

![Why AI Sales Calls Are Making Good Sales Reps Even Better [2025 Guide] ai sales calls](https://blog.peakflo.co/wp-content/uploads/2025/09/65168cf6-3001-4733-8cbc-12d5684cf449-218x150.webp)